The draw ratio is among the most important elements to be considered when attempting to deep draw a round cup.

Deep draw stamping lubricant.

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch.

When etna started operations in 1943 we began providing our drawing and stamping fluids and lubricants to produce shell cases for ammunition.

Oakite gardolube vp 10300 1 is a water soluble blend of highly refined natural lubricant components with corrosion inhibitors and a non silicone foam suppressant for use on steel copper brass and aluminum.

The draw ratio is the relationship between the size of the draw post and the size of the blank.

The draw ratio must fall within acceptable limits to allow metal to flow.

Deep stamping pastes cutting and stamping lubricants complete range of lubricants intended for cutting punching fine blanking stamping deep drawing operations with ferrous and non ferrous metals.

It is thus a shape transformation process with material retention.

Generally the effectiveness of a deep drawing lubricant depends on its ability to form an adsorbed film of sufficient strength and oiliness on the metal surface being drawn.

The deep drawing test conducted at test speeds and with bhf comparable to those present in practical stamping is a reliable test for evaluating stamping lubricants.

Stainless steel deep drawing stamping lubricant.

We are manufacturer supplier exporter of lubeco metalworking lubricants speciality lubricants neat and water based oils punching oils water based stamping oils drawing oils forming oils mist coolants from pune maharashtra india and we serve worldwide but mostly target asian middle east countries.

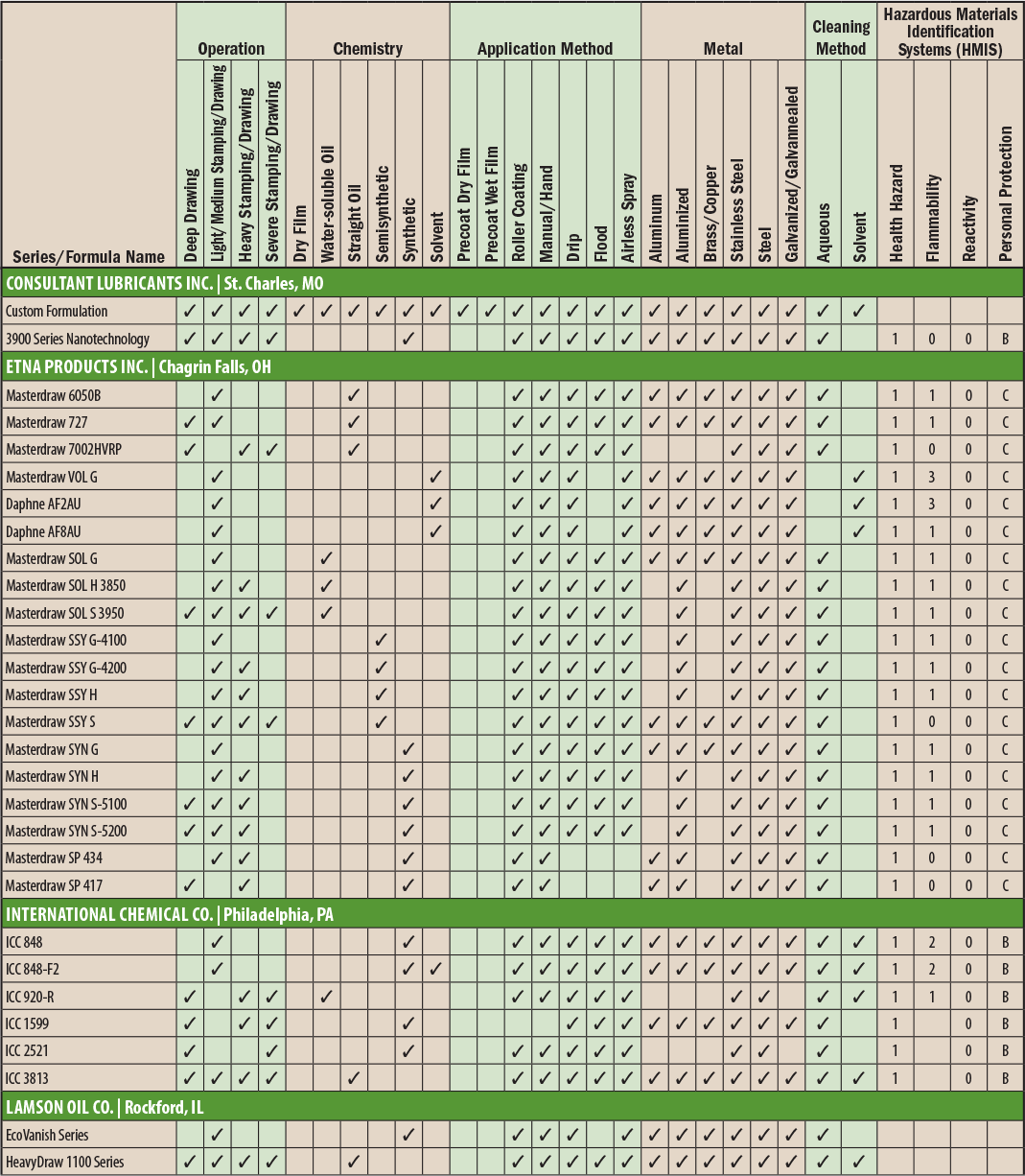

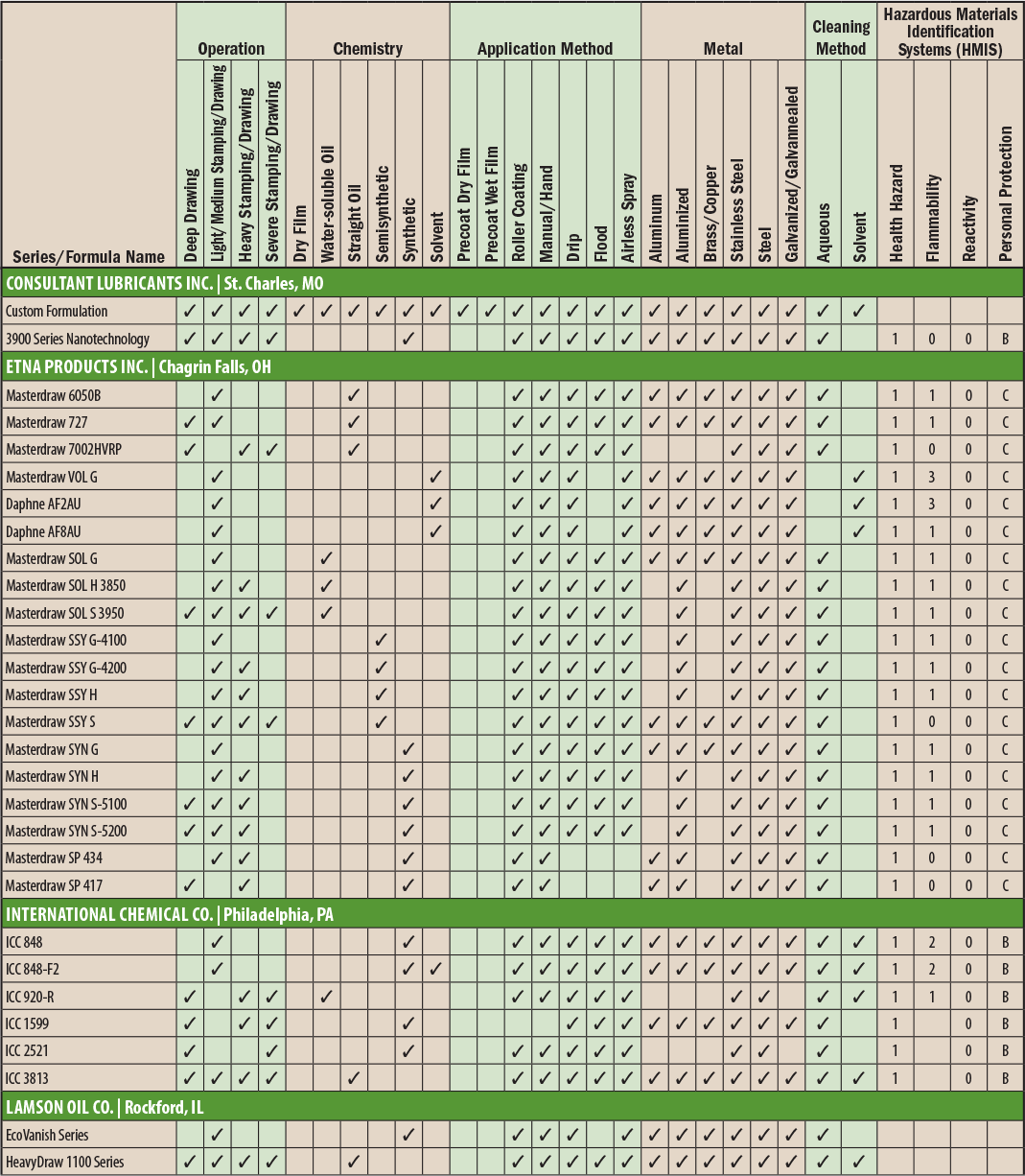

Three types of drawing lubricants are used.

The process is considered deep drawing when the depth of the drawn part exceeds its diameter.

Ashburn deep draw is a heavy duty water soluble drawing compound designed to be used in a wide range of applications and severities.

An array of applications including blanking piercing bending forming stamping and deep drawing.

Has over 70 years of experience developing formulating and manufacturing neat oil and water soluble oils for deep drawing and stamping operations.

Difficult chipless machining processes like drawing stamping finish blanking on iron and non iron materials as for plug and mandrel drawing stainless steel alloys.